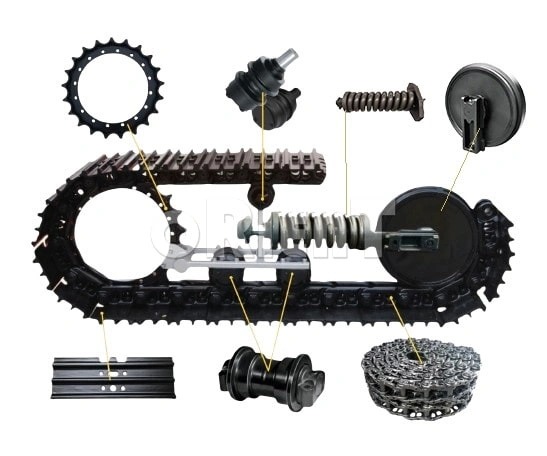

The main function of the LIEBHERR LTR1060 idler is to support the weight of the rotary drilling rig and crawler crane, allowing the crawler to move along the idler.

| Goods description | Idler, Front wheel |

|---|---|

| Applicable | LIEBHERR LTR1060 |

| Heat treatment | Whole quenching and tempering, then surface hardening |

| Production time | 7-25 days after receiving the payment |

| Loading port | Qingdao, Yantai, Dalian, Shanghai, Shenzhen, etc. |

| Packing | Plywood pallet or iron pallet |

| Trade terms | EXW, FOB, CFR, CIF, DDU, DAP |

| Payment terms | T/T, L/C, or negotiate |

| MOQ | 1 piece |

| Warranty time | 1 year |

Designed to support the track, distribute the crawler crane's weight, and provide traction and stability, the idler is produced through casting.

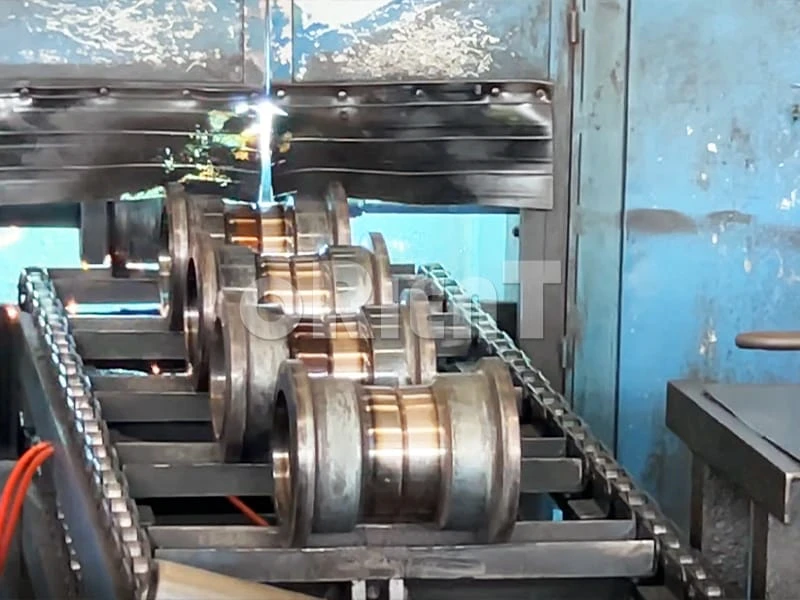

This process significantly enhances the material's density and crystallinity, endowing the idler with exceptional tensile strength, compressive strength, and wear resistance, thereby boosting its overall mechanical properties.

We use forging technology, which can control the dimensional accuracy of the product to a certain extent, ensure that the dimensions of the guide wheel meet the design requirements, and improve the assembly accuracy and stability of the idler.

Packaging types: plywood pallet, plywood cases, and iron pallet.

We can transport by by sea, train, truck, and air. Express delivery includes: FedEx, DHL, EMS, etc.

| Brands | Models |

|---|---|

| Liebherr | HS842HD, HS852HD, , HS853HD, HS853HD/VRM, HS843HD, HS872HD,HS855HD, HS872HD HS873HD, HS875HD, HS883, HS883HD, HS885HD, HS895, HS895HD, HS8100HD, HS8130HD, LTR1060, LTR1100, LR1100, LR1130, LR1160 |

| Sennebogen | 3300, 5500, 650HD, 690HD, |

| Bauer | MC76, MC86, MC64, MC96, MC128 |

Can't find the model you want? Please let us know what you need,and we can customize for you!

Yes, you can. We cooperate with many forwarders. If you need, we can recommend some forwarders to you and you can compare the price and service.

If there are any parts in stock , our delivery time is only 0-7 days. For customised products: usually within 25 days of production.

Sea, train, truck, air, express.

For all products, we have a complete QC system. From the selection of raw materials for products - production process and equipment - quality inspection before delivery, all processes are strictly controlled until the completion of packaging to ensure high-quality products for customers.

We will choose the most appropriate packaging method for each product. In general, we use plywood pallet, steel pallet, plywood case.

Provide Parts Manual We Can Customize For You!