LIEBHERR HS841HD track shoe is suitable for LIEBHERR HS841HD crawler crane, its main function is to increase the contact area with the ground. With the advanced technology, the track shoe has long service life.

| Product name | Track shoe, track pad, track plate |

|---|---|

| Suitable model | LIEBHERR HS841HD |

| Material | 25MnB |

| Colour | Black, blue or as require |

| Technique | Casting or forging |

| Heat treatment | Quenching and tempering |

| Packing | Plywood pallet |

| Loading port | Yantai, Qingdao, Shanghai, Guangzhou, Yiwu, etc. |

| Trade term | EXW, FOB, CFR, CIF, DDU, DAP |

| Condition | 100% brand new |

| Warranty | 1 year |

Track shoe is one important parts of the whole crawler crane undercarriage parts. With the track chain, rollers, sprocket and idler, tensioner and matched bolt and nut together, it plays key role of the walking system and decide the service life of whole machine.

Standard size, strict quality control, more stable and durable.

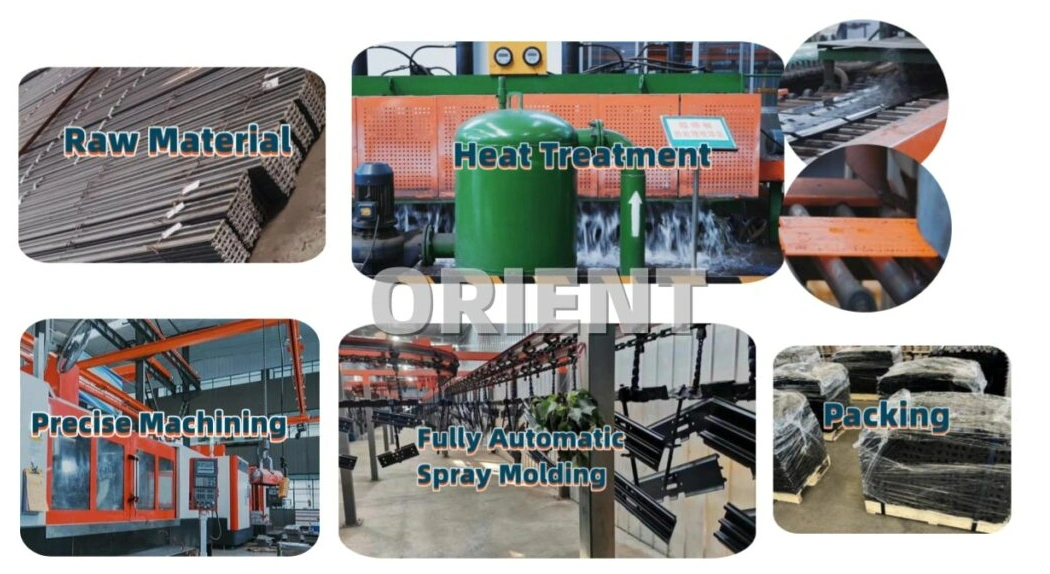

Strict quality control. Each production link will be controlled strictly by our engineer, from the raw material, heat treatment, straightening, painting and so on.

Standard size. Different length match the corresponding thickness, make sure the track shoe not easy to bend.

More stable and durable. Efficient heat treatment process, make the track shoe more stable and durable.

Cutting → Punching → Heat Treatment → Straightening → Painting → Inspection → Packing

Usually we will pack the track shoe with plywood pallet or case. The packages we use all meet the export standard and are strong enough to ensure the security of all track shoes.

Multiple shipping options. Sea, air, express and even railway are all available.It’s based on goods weight and transportation time, strive to make sure each customer to receive the track shoes at their convenience and shortest time.

Yes, you can. We cooperate with many forwarders. If you need, we can recommend some forwarders to you and you can compare the price and service.

If there are any parts in stock , our delivery time is only 0-7 days. For customised products: usually within 25 days of production.

Sea, train, truck, air, express.

For all products, we have a complete QC system. From the selection of raw materials for products - production process and equipment - quality inspection before delivery, all processes are strictly controlled until the completion of packaging to ensure high-quality products for customers.

We will choose the most appropriate packaging method for each product. In general, we use plywood pallet, steel pallet, plywood case.

Provide Parts Manual We Can Customize For You!