What Goes Into Making Piling Rig Track Rollers?

From raw material to finished product, every track roller undergoes a meticulous journey. Why is this so crucial? Because their durability directly impacts a piling rig’s performance and safety on site.

Material Selection: The Strong Start

It all begins with the right stuff. We choose high-quality alloy or carbon steel for its toughness and wear resistance. Every batch is rigorously tested to guarantee it meets our strict standards for durability.

Machining: Shaping with Accuracy

Next, raw steel is precisely shaped. This involves cutting, followed by turning on a lathe for exact dimensions and a smooth finish. We use drilling, boring, and milling to create specific features, ensuring every detail is perfect.

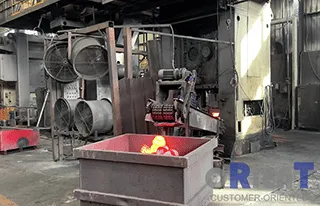

Heat Treatment: Building Hardness

Here’s where the strength comes in. Machined rollers undergo specialized heat treatment, like quenching and tempering, to boost their hardness and durability. Techniques such as induction hardening create a super-tough surface while keeping a strong core. A final polishing step reduces friction even further.

Assembly: Seamless Integration

Now, it comes together. Bearings are carefully installed for smooth rotation, and robust seals are added to protect them from dirt and moisture, extending their life. Proper lubrication ensures everything moves effortlessly.

Quality Control: Guaranteeing Excellence

No roller leaves our facility without passing rigorous checks. Each one is inspected for dimensional accuracy and finish. We also conduct functional testing to ensure they operate perfectly under the toughest conditions. This meticulous quality control guarantees top performance on every job site.

The detailed production of piling rig track rollers highlights our commitment to engineering excellence, ensuring these vital parts contribute to efficient, reliable, and safe foundation work worldwide.

If you have any inquiries regarding our Drilling Rig Undercarriage Parts—such as track shoes, track chain assembly, track roller, carrier roller, sprocket, or idler—please do not hesitate to contact us.