This sprocket is used for rotary drilling rigs BAUER BG20, with high hardness, wear resistance and durability. It can be used in deep foundation operations such as bridge pile foundations, port pile foundations, and high-rise building construction, etc.

| Goods description | Sprocket, drive wheel |

|---|---|

| Applicable | BAUER BG20 |

| Heat treatment | Whole quenching and tempering, then surface hardening |

| Production time | 7-25 days after receiving the payment |

| Loading port | Qingdao, Yantai, Dalian, Shanghai, Shenzhen, etc. |

| Packing | Plywood pallet or iron pallet |

| Trade terms | EXW, FOB, CFR, CIF, DDU, DAP |

| Payment terms | T/T, L/C, or negotiate |

| MOQ | 1 piece |

| Warranty time | 1 year |

This sprocket is specially designed for the undercarriage of Bauer BG12 rotary drilling rigs. It is made of alloy steel. After heat treatment, the hardness is increased and the wear resistance is improved by 20%.

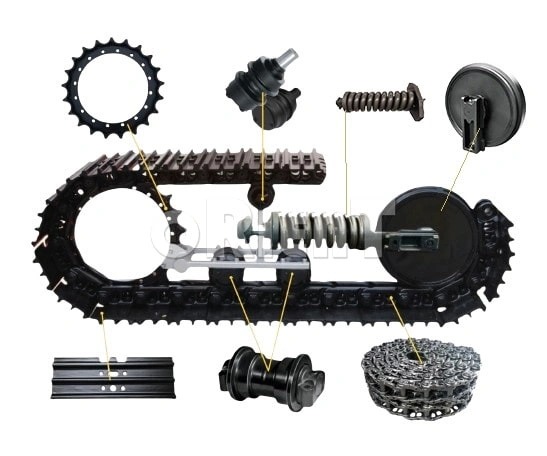

The sprocket is connected to the reducer to provide power for the machine. Through the meshing of gears and crawlers, the power transmitted from the motor to the reducer is transmitted to the crawler, thereby driving the crane forward.

Precisely adapted to mainstream models such as BAUER, LIEBHERR, SOILMEC, MAIT, Sany, and XCMG. Suitable for harsh environments such as bridge pile foundations and mine drilling.

Mold manufacturing + Casting + Quenching and tempering medium frequency treatment (heat treatment) + Drilling and grinding and other treatments (finishing) + Painting and packaging

Packaging types: wooden pallet, iron pallet, wooden box packaging.

We can transport by air, sea, truck, rail, etc. Express delivery includes: FedEx, UPS, DHL, EMS, etc.

Yes, you can. We cooperate with many forwarders. If you need, we can recommend some forwarders to you and you can compare the price and service.

If there are any parts in stock , our delivery time is only 0-7 days. For customised products: usually within 25 days of production.

Sea, train, truck, air, express.

For all products, we have a complete QC system. From the selection of raw materials for products - production process and equipment - quality inspection before delivery, all processes are strictly controlled until the completion of packaging to ensure high-quality products for customers.

We will choose the most appropriate packaging method for each product. In general, we use plywood pallet, steel pallet, plywood case.

Provide Parts Manual We Can Customize For You!