What Are The Precautions For Replacing The Track Roller?

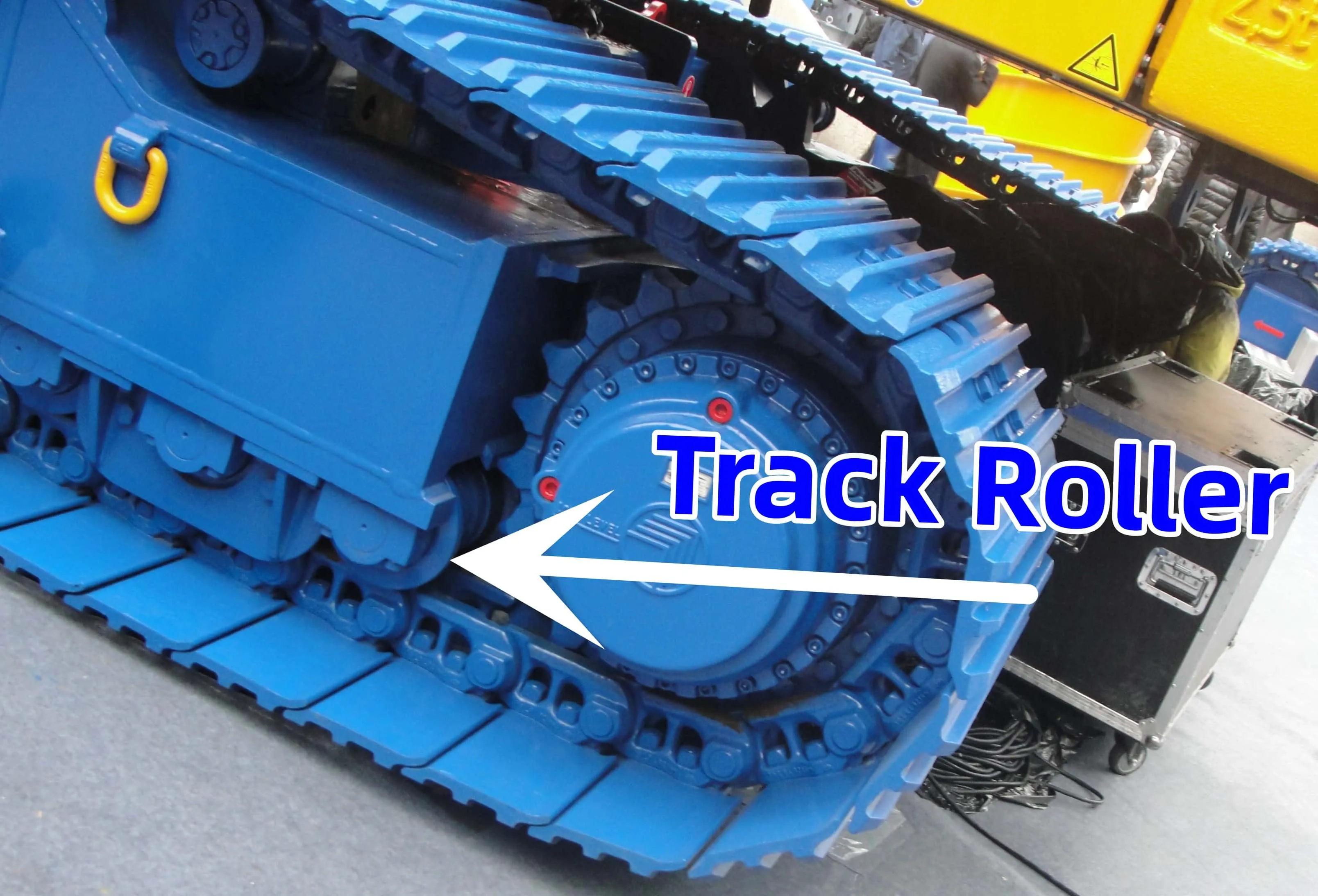

What is track roller?

The track roller mainly serves as a support and is located between the lower surface of the left/right beam of the underframe and the crawler. Depending on the tonnage of the machinery, there are usually 5-10 track rollers on each side.

Steps for replacing the track roller:

① Clean the mud and debris from the walking rack and park the equipment on a flat area.

② Use a wrench to loosen the pressure relief plug of the tensioning cylinder of the traveling frame. And do not loosen it more than one turn to prevent high-pressure grease from spraying out and injuring people.

③ Use a working device (boom cylinder) to support the vehicle body, lift the track shoes. And use a pneumatic wrench to loosen the screws on the track roller cover, but do not completely remove the screws.

④ Lift the boom oil cylinder. Lower the track shoe. Support the track shoe with the track roller. Loosen the screws and remove the cover. Support the vehicle body again, and lift out the track roller.

⑤ Install the track roller in the disassembly sequence. The roller screws are coated with copper powder to prevent rust. After screwing in place with an air wrench, the weight gauge (torque tool) can be adjusted to the specified value to add weight.

⑥ After injecting high-pressure grease into the telescopic cylinder of the traveling frame, measure the front and rear travel to the standard value.

Related News

We often say our parts are “high-quality,” but what does that truly entail? With our latest shipment of Track Rollers (P/N: 3216719980) now en route to our partners, we want to lift the curtain and reveal the tangible engineering and rigorous processes that define this standard.

A regular customer ordered Doosan DX480 undercarriage parts. Thanks for the customer’s trust and long-standing cooperation. It lets us have enough motivation to improve the product quality and our service. Everyone in our team is dedicated to their duties as always, until the goods are shipped.

Shipment of Crawler Crane Sumitomo LS118RH3 Insert Boom Date: 22th, August, September, 2022 Description of Goods:

Dubai blue sky hotel project is the highest hotel building in the world, covering an area of 3662 square meters and a building area of about 102000 square meters. It includes 1100 hotel rooms, 320 meters high-altitude open-air swimming pool, 360 meters high-altitude restaurant and 5-level high atrium hanging garden. The structural design is complex, the construction is difficult and very cumbersome.

Shipment of CAT D4H Bulldozer Swamp Shoe Date: 11th, February, 2021 Description of Goods: 142 Piece of CAT D4H Bulldozer Swamp Shoe Total Weight: 3 TONS

Wear of the crawler track. Wear between the track pin and the pin bushing is inevitable, but this wear will stretch the track pitch and make the track too large. If this wear continues, the track will move sideways, causing wear on the idler, track rollers, and sprockets, while also exacerbating the wear on the track pin and bushing.

In the grand blueprint of infrastructure construction, every rotary drilling rig plays a crucial role. But have you ever wondered why some equipment can operate consistently and efficiently under harsh working conditions, while others frequently malfunction? The answer often lies in unnoticed details, such as the unsung hero of the rotary drilling rig – the chain guard.

Tired of constant downtime and rising maintenance costs caused by undercarriage failures? We understand how critical reliable undercarriage components are to your operations. That’s why we supply top-quality Mait HR180 undercarriage parts engineered for durability, performance, and seamless integration.

A regular customer from the United Arab Emirates, cooperating for many years, has been buying parts from us continuously. Recently, they ordered 2 complete sets of KR806-4 undercarriage parts, some are customized parts with drawings. Now all the goods have been sent to Qingdao port, have been released from customs, just waiting for the vessel departure.

As a supplier of undercarriage parts for rotary drilling rigs, we understand that customization is key to enhancing performance and longevity. To streamline the process and ensure precision, here’s how we optimize customization based on your specific needs: