The Production Strength of the Tensioner Assembly

In-depth Exposing | The Production Strength of the Tensioner Assembly – Full Process Analysis from Material Selection to Testing

In the undercarriage system, the tensioner assembly is the core component to ensure the stable operation of the track. Its performance is directly related to the equipment life and construction efficiency. Today, we will take you to understand the birth process of high-quality tensioners from the perspective of production and manufacturing!

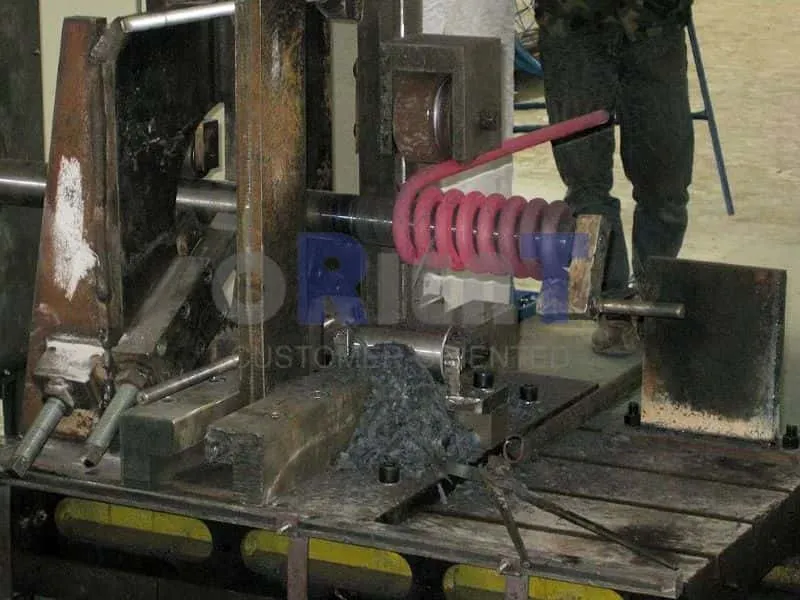

1. Spring Manufacturing: Core Support under High Stress Conditions

Material selection: alloy spring steel is used, which has high strength, strong toughness and excellent fatigue resistance.

Process:

Rolling: precision molding using CNC spring winding machine to ensure the consistency of the number of turns and pitch.

Heat treatment: quenching + tempering to maintain stable hardness

Stress shot peening: increase surface compressive stress and increase fatigue life by more than 30%.

2. Cylinder assembly: double guarantee of sealing and pressure resistance

Cylinder processing:

Material: 45# steel precision honing

Sealing system: imported polyurethane sealing ring, resistant to high pressure and aging, suitable for extreme environments of -30℃~120℃

2. Strict factory testing, zero compromise on quality

Tensile test, sealing test, environmental simulation

We have been focusing on construction machinery chassis components for 15 years, using precision manufacturing to protect the stable operation of each excavator! been focusing on engineering machinery chassis components for 15 years, using precision manufacturing to protect the stable operation of every excavator!